Content

Various inlays not only ensure optimal presentation, but also serve to protect your products. From foam, cardboard to sustainable inlays - every inlay option can be tailored to your product.

The different inlay options always have their own advantages, whether in terms of price or type of application. Let us inspire you and discover a selection of our design options for your packaging. We are sure - we have the suitable inlay for your product, too!

You already have a concrete idea for your inlay or need individual advice? Then contact our packaging experts now - we will be happy to help you!

Cardboard inlays

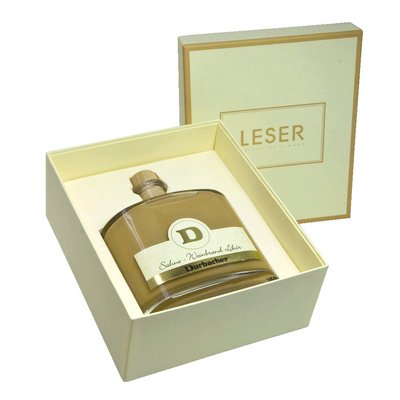

Cardboard inlays are among the most popular inlays for individual customer projects. They can be designed individually by the customer, are robust and have relatively low tool costs. For an optimal hold and for a better fixation of your product we develop and produce the suitable cardboard inlay on your request. Several articles can also be ideally placed in a gift packaging in this way. Different product levels are also possible.

This environmentally friendly and sustainable inlay option is machine-punched in our production facility in southwest Germany and is flexible in its design. Cardboard inlays can be made of corrugated cardboard as well as solid cardboard. Basically, this type of inlay is suitable for all our packaging and liftoff boxes. Only in the case of round packaging or boxes in special shapes does any feasibility need to be checked in each individual case. There are almost no limits to the colour possibilities.

Foam inlays

Especially in the jewellery sector, flocked foam inlays are one of our long-standing favourites. Adapted to your product, we develop a precisely fitting recess with you, so that a secure hold and an attractive product presentation is guaranteed. For the fully automatic production of these inlays, only a punching tool is required, which is why this type of inlay is one of our most cost-effective. The foam, available in the colours white and black, is flocked on the upper side to give it its velvety feel.

Since the introduction of our 0150 RECYCLE series, we also offer a foam that is made of 100% recycled materials. Instead of thermal recycling, foams that have already been used are thus given a second life. The foam is reprocessed and reassembled to form new pieces of inlay and still guarantees the same properties as conventional foam inlays: no damage and no tarnishing!

Thermoformed inlays

Thermoformed inlays are produced by means of thermal deformation. In this process a thin plastic sheet is heated to make it soft and malleable. Usually polystyrene is used for this purpose, but more sustainable raw materials such as PLA or RPET are also being used more and more frequently. The heated sheet is then pulled over a negative mould where it hardens. This process enables any conceivable and perfectly fitting shape for your product. Different heights that your product has can be compensated in this way. On your request, thermoformed inlays can be finished with flocking. Due to relatively high tooling costs, however, the thermoformed inlay is only economically viable for higher quantities.

Cotton wool inlays

Cotton wool has been a popular inlay material for decades and is also frequently used in the jewellery industry. Our 0120 ELEMENT series is also equipped with an inlay of cotton wool.

The cotton wool is usually punched into the correct shape and then loosely placed in the bottom of the package. It can therefore be removed at any time and can also be used as a cover for your product. Due to its soft feel, cotton wool is the ideal and cost-effective inlay for jewellery, precious stones and promotional gifts. CDs and other sensitive objects can also be safely packed in this way.

packing & tissue paper

Other popular inlay materials are packing & tissue papers. Suitably crumpled and laid out, it ensures an attractive and elegant product presentation. It adapts to the respective, individual product shape without the use of tools and also offers protection against shocks during shipping. It is therefore particularly suitable for sensitive products such as glasses or bottles. There is also the possibility to wrap your product in the packaging with a sticker using packing paper or tissue paper to offer your customers a special unpacking experience.

Contact us for more information about our possibilities and colours of packaging & tissue papers!

SizzlePak

SizzlePak is another environmentally friendly inlay material. This material is kraft paper cut into strips. This inlay material is particularly suitable for large-volume and heavy products, such as wine bottles, because of its shock-absorbing effect. Basically, SizzlePak can be used in any imaginable box. However, it is not suitable for small products.

- 100 % recyclable

- antistatic

- dust-free

Handmade inlays

At your request we can also manufacture inlays completely by hand in our company. The raw body of the inlay is adapted to your product and finally coated with the desired material. This process is very time-consuming and costly, which is why handmade inlays are only recommended for particularly high-quality products or for medals & orders in small quantities.

Finishing & printing

Give your packaging its own touch with your design and/or logo. There are various printing and embossing options to meet your wishes.

Click here to find out more