Content

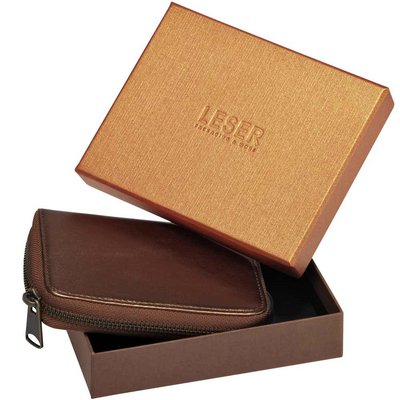

- Hot foil embossing – The classic

- Offset Printing

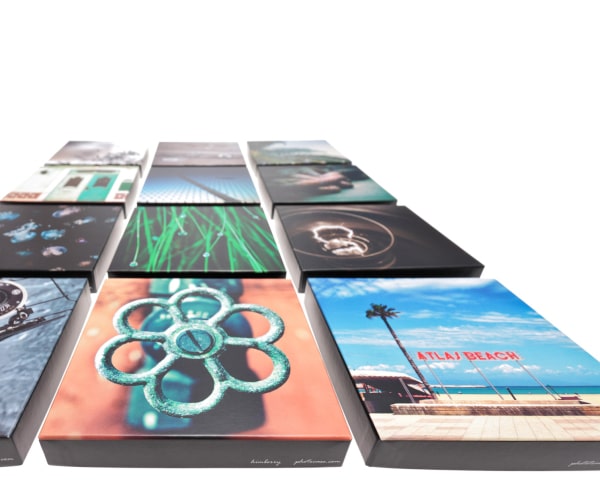

- Digital Printing

- Further options for individual finishing

- LIGHTPACK BY LESER: Luminous packaging

With our various possibilities for individualisation, a simple packaging becomes your own exclusive sales packaging. No matter whether it is a cardboard box with a slip lid or a plastic case - you can choose from many different finishing options. Turn your packaging into a brand ambassador and develop with us an impressive and elegant sales packaging with recognition value!

No matter whether small quantities or large print runs - there is a suitable solution for every requirement. Let yourself be inspired and discover our wide range of possibilities that will make your packaging something special!

Hot foil embossing - the classic

Hot foil embossing expands the range of finishing possibilities immensely. In addition to visual effects, this process can also be used to create haptic effects that allow even small quantities to be impressively and individually designed. With this widely used variant, a heated stamp, also known as a cliché, presses particles from a foil strip onto your packaging under high pressure. Find out about the different hot foil embossing processes!

The embossing process

Despite different embossing processes, the process usually proceeds as follows:

Adobe Illustrator: .ai; Adobe Photoshop: .psd; Adobe InDesign: .indd - images embedded; other graphic formats: tif, eps, jpg, pdf - min. 300 dpi;

Preference is given to vectorised graphics!

- You send us your logo or your desired finishing motif. Supported programs and file formats:

- After checking the file and approving the motif correction, a special embossing stamp made of brass is produced in the desired motif size.

- Your product is then embossed in our fully automatic or manual embossing plant. It is important that all parameters, such as contact pressure, temperature and holding time are optimally coordinated.

For embossing with hot foil there are one time costs for the production of the embossing stamp and unit costs for the embossed packaging.

Our colour options

For finishing with the hot foil embossing process you can choose from a wide range of colour foils. There are hardly any limits to the possibilities here, but certain films are more suitable for certain types of packaging than others. Here you will find more information about printing with hot foil and selected examples of the colour possibilities.

Offset Printing

The offset printing process is one of the standard printing processes in every modern printing company. The use of the CMYK, Pantone or RAL colour system ensures a very accurate reproduction of the colours you require. With this printing method you have the possibility to print whole landscapes, photos and much more on your packaging. The process impresses with an extremely high quality and speed, as well as a uniform print image. To give your colours an additional brilliance and protection, the printed image is additionally varnished colourless in gloss or matt.

You can print in offset already from a quantity of 1,000 pieces. However, it becomes economically highly interesting only from a quantity of 10,000 pieces.

Digital Printing

In contrast to the offset technique, digital printing is already worthwhile for smaller print runs. The digital printing process works in the same way as your ink-jet or laser printer at home, where colour is selectively applied or sprayed onto the print object. Thus, no physical solid printing object is required to which the colour to be printed is applied in advance. Tool costs are saved, set-up times are minimised and each sheet can be printed differently with relatively little effort. Digital printing is very interesting in terms of price, especially for short runs, and leaves a lot of room for your ideas.

Further finishing options

Foil lamination

On request, all cover papers can be laminated or coated with a matt or glossy film. This increases the protection of the printed packaging - e.g. against rain, scratches, etc.

UV spot coating

Certain areas or lettering on your packaging can be highlighted by a UV spot coating. This finishing variant sets smaller highlights within the print motif and thus makes your packaging something special!

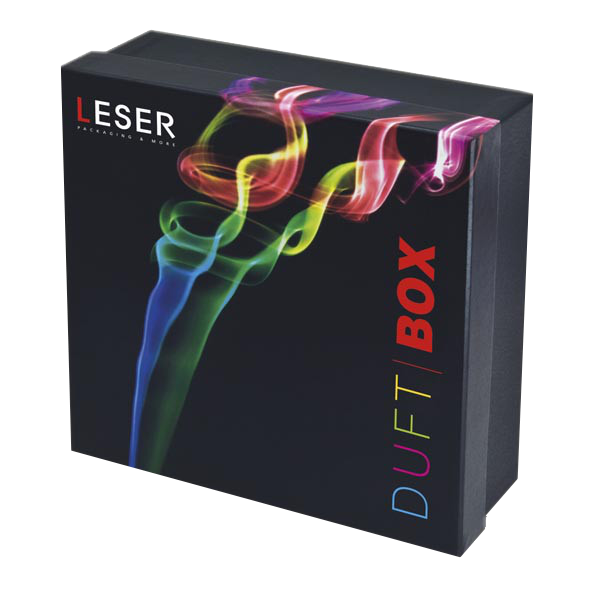

Scent-box - The packaging with smell

The gift packaging that not only looks good, but also smells good. You have the choice of more than 100 fragrances!

LIGHTPACK BY LESER: LUMINOUS PACKAGING

If you are looking for particularly eye-catching packaging, LIGHTPACK BY LESER is the right place for you.

Today's innovative spirit demands creative and novel packaging for a wide range of industries and products. At LESER, we have put our know-how and progressive thinking into the development of sophisticated luminous packaging so that you can present your products in a contemporary and exclusive way.

Ensure the WOW effect for your customers and use the innovative packaging as a means of communicating your own values.

From a minimum order quantity of 5,000 pieces, we will produce luminous packaging for you that is guaranteed to cause a big stir and be remembered for a long time.

Inlay options

In order to protect and present your product to best advantage, you have at your disposal a wide range

of inlay options. From foam, paperboard to plastic -

there is a wide selection of possibilities.

Click here to find out more!